The Pruftechnik Rotalign Touch is a powerful tool for precisely aligning machinery. Its intuitive interface and advanced technology make it easy to obtain optimal alignment, minimizing wear. This results in increased machine performance, lowered maintenance costs, and prolonged equipment life. By utilizing the Rotalign Touch's features like its touch screen display, laser technology, and built-in alignment routines, technicians can confidently align rotating shafts with remarkable accuracy.

- Outcomes of using the Rotalign Touch include:

- Lowered downtime

- Improved machine efficiency

- Lengthened equipment lifespan

With its user-friendly design and effective functionality, the Rotalign Touch is a valuable asset for any maintenance team seeking to enhance machinery alignment.

Unlocking Safety and Efficiency with IRISS Flex-IR

Enhance your operational safety and streamline your workflows with the revolutionary IRISS Flex-IR. This cutting-edge solution provides real-time, non-contact infrared sensing, enabling you to identify hot spots quickly and efficiently. The Flex-IR's lightweight construction ensures easy access and maneuverability in even the most confined spaces. With its simple operation, you can make informed decisions with confidence.

- Reduce the risk of incidents by proactively identifying potential thermal stress.

- Optimize your maintenance schedules based on real-time temperature data.

- Ensure fulfillment of industry best practices

The IRISS Flex-IR is the perfect choice for industries that prioritize efficiency, such as manufacturing, energy, transportation, and more.

Smart Lubrication Management: Introducing SDT Lubexpert

Modern industrial operations demand precise control and unwavering reliability. SDT Lubexpert emerges as a revolutionary solution for efficient lubrication management, empowering businesses to optimize asset performance and minimize downtime. This cutting-edge system harnesses the power of sensors to provide real-time insights into the health of your machinery's lubrication systems. By continuously analyzing key parameters like oil temperature, viscosity, and contamination levels, SDT Lubexpert enables you to predict potential issues before they escalate into costly failures.

- Enjoy unparalleled visibility into your lubrication assets with comprehensive data visualization.

- Optimize your lubrication routines for enhanced efficiency and reduced maintenance costs.

- Maximize the lifespan of your equipment through timely intervention and preventive maintenance.

SDT Lubexpert is more than a monitoring system; it's a strategic partner that empowers informed decision-making. With its user-friendly interface and actionable insights, SDT Lubexpert upgrades lubrication management, driving operational excellence and maximizing your bottom line.

Streamlining Predictive Maintenance with Advanced Technologies

Predictive maintenance is revolutionizing the way industries manage equipment upkeep. By leveraging sophisticated technologies such as artificial intelligence, businesses can now forecast potential issues before they occur. This proactive approach not only minimizes downtime but also enhances operational productivity. Advanced sensors collect real-time metrics on equipment performance, which is then analyzed by models to identify trends of impending issues.

- This data-driven insight enables technicians to perform maintenance beforehand, minimizing disruptions and increasing equipment lifespan.

- Additionally, predictive maintenance can enhance resource allocation by targeting specific areas that require care.

By embracing these advanced technologies, industries can achieve a significant improvement in their here maintenance strategies, resulting in substantial cost savings and operational superiority.

Optimizing Industrial Operations Through Precision Measurement

In today's intensely competitive industrial landscape, reaching optimal operational efficiency is paramount. Precision measurement plays a pivotal role in this endeavor, enabling producers to monitor critical parameters with unprecedented accuracy. By implementing advanced measurement instruments, businesses can control production discrepancies, adjust processes, and finally enhance overall productivity.

Maintaining measurement data with real-time operational insights allows for foresightful evaluation, facilitating continuous refinement. This leads in increased product quality, reduced production costs, and a more robust competitive standing within the market.

The Future of Condition Monitoring: Innovative Solutions for Industry

Condition monitoring is rapidly evolving in the manufacturing landscape. Employing cutting-edge technologies such as machine learning, condition monitoring systems can proactively identify potential failures before they occur. This optimizes operational uptime and minimizes costly maintenance. The future of condition monitoring presents exciting opportunities for industries to enhance their processes and achieve sustainable growth.

Through continuous advancements, condition monitoring is poised to transform the way organizations manage their assets, leading to a more reliable and cost-effective future. Moreover, the integration of connected devices with condition monitoring platforms will enable real-time insights into asset status, therefore empowering businesses to make strategic decisions.

Delve into some cutting-edge solutions that are defining the future of condition monitoring:

* Cloud-based platforms provide remote monitoring capabilities, enabling organizations to analyze asset performance from anywhere.

* On-device analytics brings data analysis closer to the source, improving response times.

* Transparent recordkeeping enhances data integrity and security in condition monitoring applications.

These solutions are disrupting the industry, paving the way for a more connected future of asset management.

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Scott Baio Then & Now!

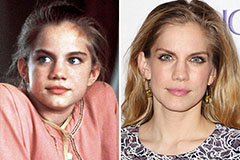

Scott Baio Then & Now! Anna Chlumsky Then & Now!

Anna Chlumsky Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Macaulay Culkin Then & Now!

Macaulay Culkin Then & Now!